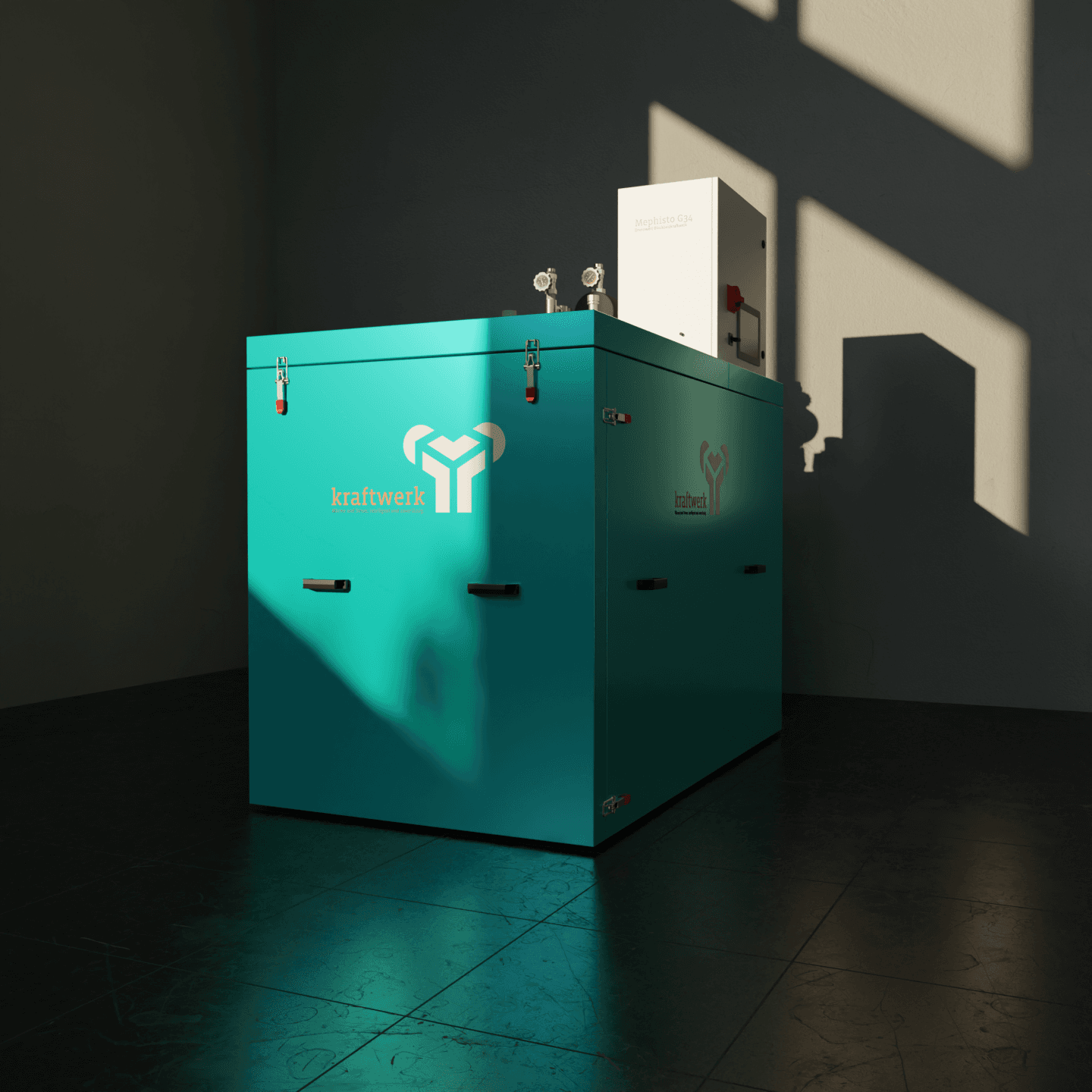

mephisto

G34

The module between conventional performance classes.

Technical data

Mephisto G34

Net output (adjustable)

Net efficiency Electric

General

Gas connection

Heating connection

Residual head for net output: 9,0 mWS

Electrical connection

- Pre-fuse NH00 80 A gL (gG) or SLS E-80 A

- Supply line H07RN-F 5 x 25 mm² to 50 m in length for installation types B to G

Plate heat exchanger

Soldered stainless steel compact heat exchanger for separating the heating system from the CHP engine water circuit

Pollutant emissions

Mephisto G34B comes below the German regulation emission limit

Combustion intake air

Space-air-dependent operating mode

Flue gas connection

- Flue gas conduit D110, fire resistance class B1 plastic pipe made of PP, permitted as a flue gas conduit for condensing heat generators with flue gas temperature up to 120 °C

- Flue gas temperature limited max. 90 °C on thermostat

- Safety thermal cut-out set to 100 °C

- Recommended flue gas counter-pressure: 500 Pa; maximum flue gas counter pressure 800 Pa

- Flue gas flow rate 117 m3/h in normal state is equivalent to 151 m3/h at TFlue Gas = 80 °C

- Maximum condensate quantity: 15 l/h

Flue gas heat exchanger

- Thermodynamically optimised cast aluminium-silicon heat exchanger

- Integrated catalytic converter

Utilisation of calorific value

- The flue gas temperature is a maximum of 15 K above the corresponding return temperature

- Calorific value used at a return temperature of about 55 °C and above

Motor

- Perkins industrial gas engine

- Model: 1004 Si

- 4-cylinder Otto engine, water-cooled

- Displacement: 4.000 cm³

Coupling

Maintenance-free, plug-in, flexible metal/plastic coupling to compensate for radial, axial and angular misalignment.

Generator

- Four-pole asynchronous machine for parallel operation on the public grid

- Manufacturer: Weier GmbH

- Model: DASGM 200/4 L water-cooled

- 3 × 400 V, 50 Hz

- Start-up current: about 224 A

- Rated current: 57,7 A

- cos φ: 0,85 (inductive)

- Rated power: 30 kW

- Rated speed: 1.538 min-1

Low voltage certification

Low voltage certification with unit certificate as per application guide VDE-AR-N 4105:2

Compensation

Due to the requirements in German code of practice VDE-AR-N 4105:2018-11, operating own generating systems without reactive power compensation is only permitted in exceptional cases. A cos φ of 0.95 is achieved with the standard fixed compensation.

Feed-in management as per §14 EEG 2021

Reduction in feed-in power (0-10 V) possible by preselecting target value via analogue input, bus interface (optional) and digital inputs (to connect relay contacts on a ripple control receiver provided by customer).

Controller

- Industrial computer with powerful MPC555 microcontroller, 32-bit power PC with FPU

- Fully automatic operating control

- Remote monitoring/operation via LAN or optional mobile data connection

- Interfaces to higher-level DDC controls: digital and analogue inputs and outputs; optional CAN bus, RK512, Modbus, LON bus, Profibus DP, BACnet/IP, IEC 104, Profinet

Housing

- Sturdy, easily removable, frameless full thermoacoustic enclosure

- Machine unit on four Asonator steel springs

Noise emissions

- Mean sound pressure level at 1 m distance ≤ 62,2 dB (A) as per DIN 45635-11

- Mean sound pressure level (standard equipment) at 1 m distance (45°) to chimney outlet ≤ 48,3 dB (A) as per DIN 45635-11

Third octave band spectra isolation can be provided on request

Dimensions

L × W × H in mm: 1.800 × 1.040 × 1300 Without electrical enclosure.

Height with electrical enclosure: 1.910 mm

Required space

L × W × H in mm: 3.800 × 2.100 × 2.280

Installation and base plans will be provided on request

Operating weight

1.350 kg

Delivery

- Machine unit, self-supporting: 1.600 mm × 800 mm, 930 kg

- Panelling with accessories on pallet: 2.000 mm x 1.200 mm, 400 kg