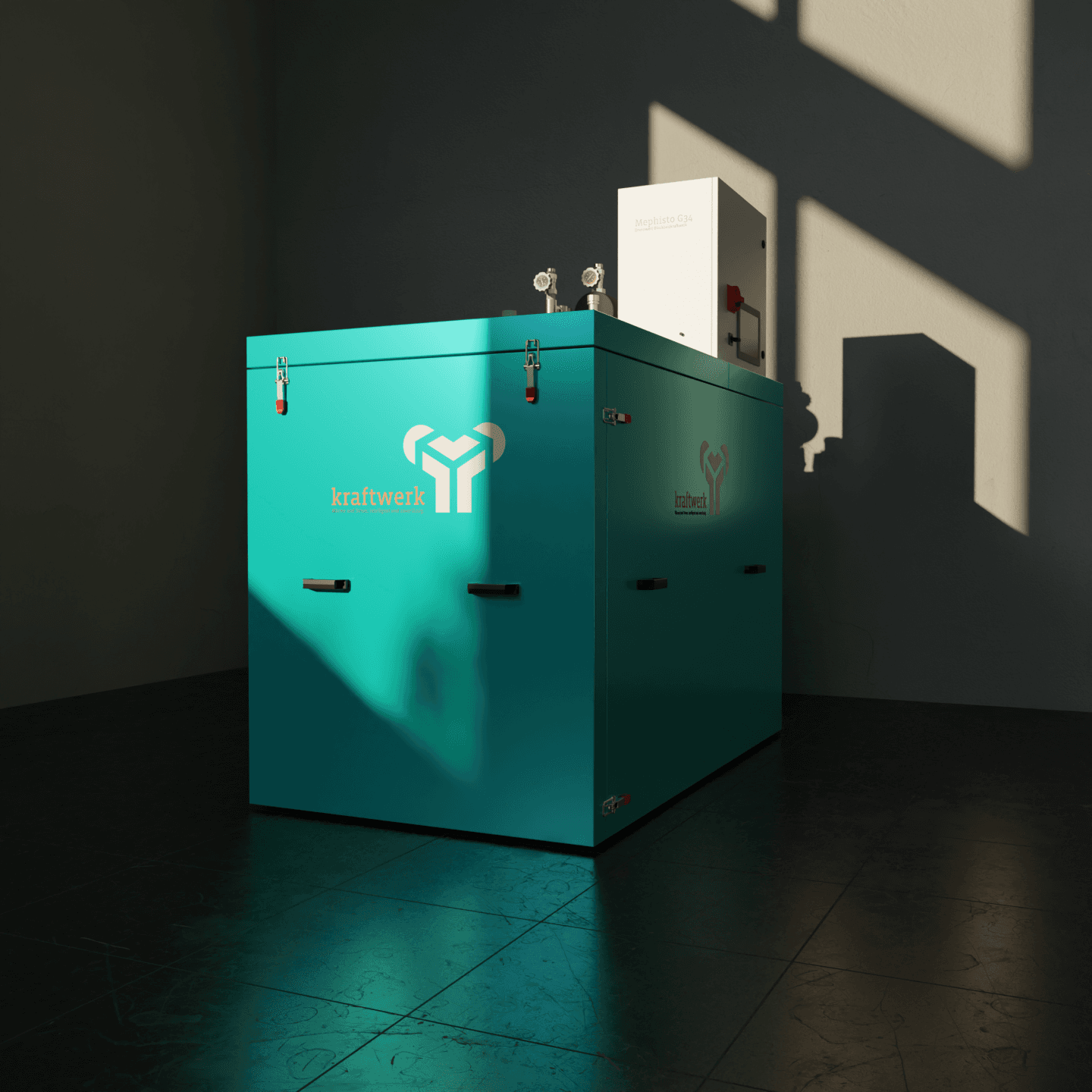

mephisto

G34

The module between conventional performance classes.

Technical data

Mephisto G34

Net output (adjustable)

Net efficiency Electric

General

Gas connection

Heating connection

Residual head for net output: 8,9 mWS

Electrical connection

- Pre-fuse NH00 50 A gL (gG) or SLS E-50 A

- Supply line H07RN-F 5 x 25 mm² up to 50 m in length for installation types B to G

Plate heat exchanger

Soldered stainless steel compact heat exchanger for separating the heating system from the CHP engine water circuit

Pollutant emissions

Mephisto G34 comes 50% below the German regulation emission limit

Combustion intake air

Space-air-dependent operating mode

Flue gas connection

- Flue gas conduit D110, fire resistance class B1 plastic pipe made of PP, permitted as a flue gas conduit for condensing heat generators with flue gas temperature up to 120 °C

- Flue gas temperature limited to max. 90 °C on thermostat

- Safety thermal cut-out set to 100 °C

- Recommended flue gas counter-pressure: 500 Pa; maximum flue gas counter pressure 800 Pa

- Flue gas flow rate: 117 mN³/h i.N. in normal state is equivalent to 151 m³/h bei TFlue gas = 80 °C

- Maximum condensate quantity: 15 l/h

Flue gas heat exchanger

- Thermodynamically optimised cast aluminium-silicon heat exchanger

- Integrated catalytic converter

Utilisation of calorific value

- The flue gas temperature is a maximum of 15 K above the corresponding return temperature

- Calorific value used at a return temperature of about 55 °C and above

Engine

- Perkins industrial gas engine

- Model: 1004 Si

- 4-cylinder Otto engine, water-cooled

- Displacement: 4.000 cm³

Coupling

Maintenance-free, plug-in, flexible metal/plastic coupling to compensate for radial, axial and angular misalignment

Generator

- Four-pole asynchronous machine for parallel operation on the public grid

- Manufacturer: Weier GmbH

- Model: DASGM 200/L 4 water-cooled

- 3 × 400 V, 50 Hz

- Start-up current: about 224 A

- Rated current: 57,7 A

- cos φ: 0,85 (inductive)

- Rated power: 30 kW

- Rated speed: 1.538 min-1

Compensation

Due to the requirements in German code of practice VDE-AR-N 4105:2018-11, operating own generating systems without reactive power compensation is only permitted in exceptional cases. A cos cos φ of 0.95 is achieved with the standard fixed compensation.

Controller

- Industrial computer with powerful MPC555 microcontroller, 32-bit power PC with FPU

- Fully automatic operating control

- Remote monitoring/operation via LAN or optional mobile data connection

- Interfaces to higher-level DDC controls: digital and analogue inputs and outputs; optional CAN bus, RK512, Modbus, LON bus, Profibus DP, BACnet/IP, IEC 104, Profinet

Housing

- Sturdy, easily removable, frameless full thermoacoustic enclosure

- Machine unit on four Asonator steel springs

- Optional base on two vibration dampers to isolate noise

Noise emissions

- Mean sound pressure level at 1 m distance ≤ 62,2 dB (A) as per DIN 45635-11

- Mean sound pressure level (standard equipment) at 1 m distance (45°) to chimney outlet ≤ 48,3 dB (A) as per DIN 45635-11

Third octave band spectra isolation can be provided on request

Dimensions

L × W × H in mm: 1.800 x 1.040 x 1.300 Without electrical enclosure.

Height with electrical enclosure: 1.910 mm

Required space

L × W × H in mm: 3.800 × 2.100 × 2.280, without sound insulation base. Height of sound insulation base: 250 mm.

Installation and base plans will be provided on request

Operating weight

1.350 kg

Delivery

- Machine unit, self-supporting: 1.600 mm × 800 mm. 930 kg

- Panelling with accessories on pallet: 2.000 mm × 1.200 mm. 400 kg